Basic information

Development history

JDSU was established in 1981. After more than 20 years of development, it has continued to implement acquisition strategies and has gradually become the leading global optoelectronics company. It is inseparable from its series of acquisition activities. According to incomplete statistics, since the acquisition of Ramar Corporation in 1999, JDSU has made at least 15 acquisitions in about 5 years in 2004, including 4 in 1999, 3 in 2000, 2 in 2001, and 3 in 2002. Second, once in 2003, two acquisitions have been made since 2004, and it is unknown which companies will be acquired in the future.

Through the acquisition, JDSU's optical devices cover almost all optical devices in the field of optical communications, from passive to active, from chips to modules, and it has developed into the big brother of optoelectronic devices. In 2003, JDSU ranked first. According to existing data, JDSU is still the world's number one.

Main products

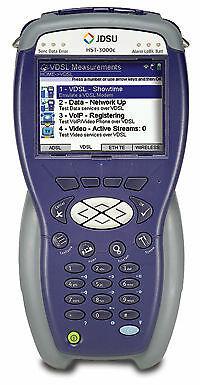

American JDSU main products:

Optical communication:

Light source, optical power meter, PON optical power meter , Optical Time Domain Reflectometer OTDR, red light pen, optical attenuator, fiber identifier, optical return loss tester, spectrum analyzer, fiber cleaning, fiber inspection microscope, etc.;

Data transmission category:< /p>

2M error tester, SDH tester, Ethernet tester, cable tester, network tester, audio generator, etc.

Product features

The main features of OTDR module and MMOTDR module:

1. Dual multimode wavelength (850nm/1300nm) or quad-mosaic wavelength (850nm/ 1300nm and 1310nm/1550nm);

2, the test range is wide, multi-mode up to 27/25dB, single-mode up to 37/35dB;

3, short dead zone ( shortdeadzone), <1m (event)/<4m (attenuation);

4. Provide continuous or modulated signal source, and connect optical power meter through SM/MM interface of OTDR module, Combining with OTDR and loss test functions, reducing the amount of maintenance tools;

5. Combining with JDSU’s Enterprise Business Application Module (ESAM), copper wire and triple play functions to provide better feedback Investment (ROI).

User interface design can effectively help engineering and technical personnel to check interface quality, automatically set parameters, loss limit testing and fiber connection, automatic analysis, and result storage management.

Related News

JDSU company launched the most advanced 40G optical network analyzer

JDSU company launched a new 40G optical network analyzer. In the current enterprise network (including: LAN network, SAN storage network and data center) applications with increasing bandwidth, this handheld device is the fastest and most advanced optical network analyzer with the fastest test speed.

It is reported that the 40G optical network analyzer of JDSU will correctly display the test results of both ends of the network after the test is completed. Testers do not need to go to the main test equipment to view the test results, which saves a lot of money testing time. In addition, the tester greatly reduces network deployment time.

Assaji Aluwihare, Director of JDSU Communication Test and Measurement Division, said: "This 40G optical network analyzer can provide the fastest and most advanced deployment for current network equipment deployment and network cable deployment. Network Test to ensure that after the network deployment is completed, it will provide users with high-quality conference calls, cloud computing and other advanced services."

The main highlights of the device:

p>*Large touch screen

*Double-ended touch screen control function;

*Reduce the time of walking back and forth;

*The network test frequency is up to 1600MHz;

*The fastest CAT6A/ClassFA tester;

*Full FA spectrum-level accurate network tester;

*Comprehensive software control system;< /p>

*Optical fiber connector end face inspector. JDSU cooperates with Amada Co., Ltd. to develop high-power fiber lasers. JDSU has cooperated with Japanese metal processing machine tool manufacturer Amada to develop fiber lasers with power up to 4kW. This marks the beginning of JDSU's entry into the high-power fiber laser market. It is reported that the fiber laser will be integrated into a new sheet metal cutting system developed by Amada. Amada introduced the system to the Japanese market in May 2011 and introduced it to the global market in June. Amada (Amada Co., Ltd.) said that the new system will provide the world's fastest linear cutting speed.

The newly developed 4kW fiber laser can cut materials that cannot be effectively cut with traditional CO2 lasers, such as copper, brass, titanium and non-metallic materials. Combined with Amada's high-speed linear drive system, the fiber laser can achieve linear cutting speeds 2.5 to 3 times faster than traditional CO2 lasers when cutting stainless steel sheets and aluminum sheets.

JDSU’s MACTrak technology solves problems for customers

JDSU’s MACTrak technology continuously solves the problems in the uplink of cable TV operators and makes the cable TV network technicians Work more efficiently and effectively. MACTrak's unique ability to demodulate real-time user modem packets in bursts of DOCSIS uplinks, real-time detection of code word errors and the ability to provide MAC addresses for each demodulated packet makes MACTrak help Operators solve problems that similar competing systems can't even see.

The continuous global deployment of DOCSIS3 clearly shows that simple solutions based on spectrum analyzers are no longer sufficient to monitor and maintain the advanced uplinks that operators face today. With the increasing demand for uplink capacity, cable TV operators are adding more carriers to their uplinks to accommodate this requirement. In addition, cable TV operators are moving from narrowband 3.2MHzQPSK or 16QAM carriers to wider 6.4MHz wide 64QAM carriers. The following items are some signs of changes for cable TV operators.

·Less overall margin (margin)-"Invisible" network impairments that were insignificant in the past are critical for 64QAM wide carriers.

·The setting of the appropriate optical level is more important than before-more carriers lead to higher power of the input laser, and a wider carrier increases the potential for laser clipping.

·Weakened the effectiveness of existing tools based on spectrum analysis. It is no longer enough to observe what is happening near or under the carrier—you need to observe what is happening inside the carrier.

In response to this trend, JDSU has developed MACTrak technology and introduced it to the market as an extension of the award-winning PathTrakTM backhaul channel monitoring system. All nodes covered by RPM3000 cards or HCU200 modules equipped with MACPack support MACTrak technology. MACTrak with code word error detection function uses in-band cable modem or DSAM data packet to inform you in real time which uplink damage is affecting the user's service. Cable TV operators may have many tools to inform their network that there are problems, but only the PathTrak system with MACTrak technology can tell you which damage is affecting the user's service through code error detection. The key to making PathTrak different from CPE and CMTS interrogation systems is that PathTrak can display in real time whether each data packet contains correctable or uncorrectable code word errors and the reason for the code word errors. Similarly, when troubleshooting on site, technicians can immediately see whether the repair can effectively eliminate the source of error in the code word. Technicians can know whether a problem has been solved or a specific problem affecting the customer has been solved.

PathTrak can observe all types of damage, including micro-reflection, group delay, and in-band spectrum response problems, which cannot be observed by the detection (monitoring) system based on a spectrum analyzer. The damage panel of the QAMTrakTM analyzer integrated into PathTrak can easily determine whether the damage is a simple intrusive noise or impulse noise problem (as opposed to more complex linear damage). The damage panel uses red/green indicator lights to show which damage is present on the node and its severity. Of course, PathTrak can detect simple intrusive noise or impulse noise problems. More difficult problems such as laser clipping can be detected in two different ways. Laser clipping can sometimes be detected by a spectrum analyzer. If there are carrier harmonics above the duplex filter, it can also be detected by PathTrak using the constellation diagram display. Even on a congested uplink, it is possible to detect impulse noise through MACTraks' automatic impulse noise detection algorithm. At the same time, PathTrak's full-featured spectrum analyzer can be used to detect out-of-band impulse noise.

When there is linear damage in the HFC network, MACTrak and the back office billing system of the cable TV operator can be used to locate it down to a small section of the network or a specific street address. Linear damage does not follow the funnel effect. Only data packets that pass through the linear impairment will be affected by the impairment. If a water-filled tap (a submerged splitter) produces a micro-reflection, only the modems (all under the splitter) that are off the tap will be affected and reported by MACTrak (MACTrak will find and report). The MAC address of these data packets can be used to dispatch the maintenance vehicle to the fault location to quickly find and repair the linear damage.

Whether it is the detection of code word errors caused by the sudden intrusion of the DOCSIS carrier, or the local cable modem performance degradation caused by the excessive group delay of the detection amplifier, countless success stories prove JDSU’s MACTrak Technology solves the most difficult uplink problem faced by technicians. By real-time detection of coding word errors in the data packet and displaying the cause of the coding word error in a simple and easy-to-understand format, MACTrak has proven to be an extremely valuable tool for field technicians. Advanced damage charts and exportable detailed data tables have attracted more and more leading network engineering teams. Regardless of your job in HFC maintenance and repair, MACTrak technology will help you solve the most difficult uplink problems.

JDSU won Huawei’s "Outstanding Core Partner Award"

CNII Network News JDSU won the award from Huawei, the world’s leading telecom optical network solution provider "ExcellentCorePartnerAward" (ExcellentCorePartnerAward). JDSU is one of only two optical component suppliers to receive this award.

JDSU won the award for providing innovative optical technology to Huawei. These innovations include reconfigurable optical add/drop multiplexing (ROADM) and tunable XFP products. JDSUROADM products can help network operators flexibly support the increasing demand for bandwidth in different parts of the optical network by increasing or reducing network capacity. This enables consumers and businesses to better use on-demand services such as voice, video, and data applications. JDSU's adjustable XFP product is a key interface that converts optical signals into electronic data when they leave the optical network. Compared with the previous transceiver products, it is reduced in size by about 85%, leaving a space for the network center control room. This saves valuable space and allows users to set up more transceivers in a "pay-as-you-go" manner without affecting network performance.

Mr. Alan Lowe, President of JDSU’s Communications and Commercial Optical Products Business, said: “Won Huawei’s “Outstanding Core Partner Award” is an important milestone in the development of JDSU. It confirms JDSU’s commitment to innovative technologies. , The promise to help leaders in the telecommunications industry improve their optical network performance."