Structure

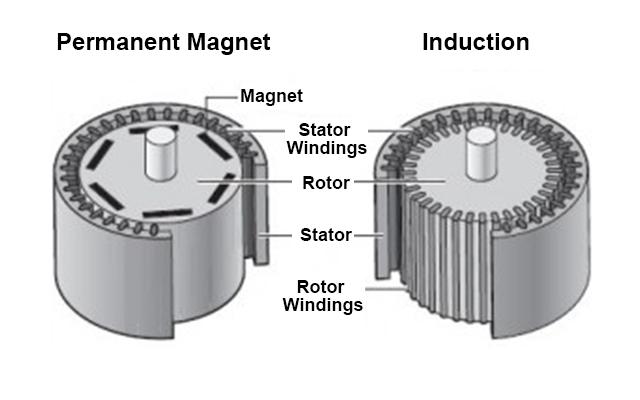

The permanent magnet synchronous motor is mainly composed of stator, rotor and end cover. The stator is laminated by laminations to reduce the iron loss generated when the motor is running. There are three-phase AC windings called armatures. The rotor can be made into a solid form, or it can be pressed by laminations, on which permanent magnet materials are installed. According to the position of the permanent magnet material on the motor rotor, the permanent magnet synchronous motor can be divided into two structural forms: the protruding type and the built-in type. Figure 1 shows the corresponding schematic diagram. The magnetic circuit structure of the protruding rotor is simple and the manufacturing cost is low, but because the starting winding cannot be installed on the surface, asynchronous starting cannot be realized.

The magnetic circuit structure of the built-in rotor mainly includes three types: radial, tangential, and hybrid. The difference between them lies in the relationship between the magnetization direction of the permanent magnet and the rotation direction of the rotor. Figure 2 shows the magnetic circuit structure of three different types of built-in rotors. Since the permanent magnets are placed inside the rotor, the rotor surface can be made into pole shoes. The pole shoes are built into copper bars or cast aluminum to play the role of starting and damping, and the steady state and dynamic performance are good. In addition, because the built-in rotor magnetic circuit is asymmetrical, reluctance torque will be generated during operation, which helps to improve the power density and overload capacity of the motor itself, and this structure is easier to achieve weak magnetic speed expansion.

Working principle

When the three-phase current flows into the three-phase symmetric winding of the permanent magnet synchronous motor stator, the magnetomotive force generated by the current synthesizes a rotation with a constant amplitude Magnetomotive force. Because its amplitude is constant, the trajectory of this rotating magnetomotive force forms a circle, which is called a circular rotating magnetomotive force. Its magnitude is exactly 1.5 times the maximum amplitude of the single-phase magnetomotive force, that is

In the formula, F is the circular rotating magnetomotive force, (T·m); Fφl Is the maximum amplitude of single-phase magnetomotive force, (T·m); k is the fundamental winding coefficient; p is the number of pole pairs of the motor; N is the number of series turns of each coil; I is the effective value of the current flowing in the coil , A. Because the rotating speed of the permanent magnet synchronous motor is always synchronous, the main magnetic field of the rotor and the rotating magnetic field generated by the circular rotating magnetomotive force of the stator remain relatively static. The two magnetic fields interact to form a composite magnetic field in the air gap between the stator and the rotor. It interacts with the main magnetic field of the rotor to produce an electromagnetic torque Te, ie

In the formula, Te is the electromagnetic torque, (N·m); 0 is the power angle, rad; BR is the rotor The main magnetic field, T; Bnet is the air gap synthetic magnetic field, T. Due to the difference in the positional relationship between the air-gap synthetic magnetic field and the main magnetic field of the rotor, the permanent magnet synchronous motor can run in either the motor state or the generator state. The three operating states of the permanent magnet synchronous motor are shown in Figure 3. When the air-gap composite magnetic field lags behind the rotor's main magnetic field, the electromagnetic torque generated is opposite to the rotor rotation direction, and the motor is in the state of generating electricity; on the contrary, when the air-gap composite magnetic field leads the rotor's main magnetic field, the electromagnetic torque generated is the same as that of the rotor. The direction of rotation of the rotor is the same, and the motor is in an electric state at this time. The angle between the main magnetic field of the rotor and the composite magnetic field of the air gap is called the power angle.

The permanent magnet synchronous motor consists of two key components, namely a multi-polarized permanent magnet rotor and a stator with appropriately designed windings. During operation, the rotating multi-polarized permanent magnet rotor forms a time-varying magnetic flux in the air gap between the rotor and the stator. This flux generates an AC voltage on the stator winding terminals, which forms the basis for power generation. The permanent magnet synchronous motor discussed here uses a ring-shaped permanent magnet mounted on a ferromagnetic core. Internal permanent magnet synchronous motors are not considered here. Because it is very difficult for magnets to be embedded in an electroplated ferromagnetic core, by using magnets of appropriate thickness (500μm) and high-performance magnetic materials in the rotor and stator cores, the air gap can be made very large (300~500μm) There is no obvious performance loss, which makes the stator winding occupy a certain space in the air gap, which greatly simplifies the manufacture of the permanent magnet synchronous motor.

Classification

Classified according to the supply mode of excitation current

Permanent magnet synchronous motor is a synchronous motor that uses permanent magnets to establish an excitation magnetic field, and its stator generates a rotating magnetic field. The rotor is made of permanent magnet material. Synchronous motors need a DC magnetic field to realize energy conversion, and the DC current that generates this magnetic field is called the excitation current of the motor.

Separately excited motor: a motor that obtains excitation current from other power sources.

Self-excited motor: A motor that obtains the excitation current from the motor itself.

Classified by power supply frequency

Permanent magnet brushless motors include permanent magnet brushless DC motors and permanent magnet brushless AC motors. All motors need frequency conversion power supply when they are running. The former requires only a square wave inverter for power supply, and the latter requires a sine wave inverter for power supply.

Classified by air gap magnetic field distribution

Sine wave permanent magnet synchronous motor: The magnetic poles are made of permanent magnet materials, and when three-phase sine wave current is input, the air gap magnetic field Distributed according to the sine law, it is referred to as permanent magnet synchronous motor for short.

Trapezoidal wave permanent magnet synchronous motor: The magnetic poles are still permanent magnet materials, but the square wave current is input, the air gap magnetic field is distributed in a trapezoidal wave, and the performance is closer to that of a DC motor. A self-control variable frequency synchronous motor composed of a trapezoidal wave permanent magnet synchronous motor is also called a brushless DC motor.

Control method

Permanent magnet synchronous motor constant voltage/frequency ratio control method

Permanent magnet synchronous motor constant voltage/frequency ratio The control method is similar to the constant voltage-frequency ratio control method of AC induction motors. The amplitude and frequency of the motor input voltage are controlled to change at the same time, so that the motor flux is constant. The constant voltage-frequency ratio control method can adapt to the requirements of a wide range of speed regulation systems.

Under the premise of not feeding back physical signals such as current, voltage or position, it can still achieve a certain control accuracy. This is the biggest advantage of the constant voltage-frequency ratio control method. The constant voltage-frequency ratio control method has simple control algorithm and low hardware cost, and has been widely used in the field of general-purpose inverters. The shortcomings of the constant voltage-frequency ratio control method are also obvious. Because there is no feedback of speed, position or any other signals during the control process, it is almost impossible to obtain the operating status information of the motor, and it is also impossible to accurately control the speed or electromagnetic torque and system performance. Generally, the dynamic response is poor, especially when the given target speed changes or the load changes suddenly, problems such as out-of-step and oscillation are likely to occur. Obviously, this kind of control method cannot control the torque and the excitation current separately, and it is easy to have a large excitation current during the control process, which affects the efficiency of the motor. Therefore, this control method is often used in general-purpose inverters with low performance requirements, such as air conditioners, assembly line conveyor belt drive control, and energy-saving operation of water pumps and fans.

Permanent Magnet Synchronous Motor Direct Torque Control Technology

Direct Torque Control (Direct Self-Control, DSC) constructs the flux linkage and electromagnetic torque model on the stator static coordinate system, The electromagnetic torque and stator flux linkage are controlled by applying different voltage vectors. The direct torque control method has the advantages of simple algorithm and good torque response. Therefore, this method has been widely used in occasions that require high transient torque response.

Due to the inherent shortcomings of control, the direct torque control method has low control frequency and large torque ripple when the speed is low. Therefore, reducing the torque ripple at low speed has also become a research hotspot in the direct torque control method. Sun Xiaohui et al. reduce the torque ripple at low speed by optimizing the voltage vector action time, and the effect is better. D.casadei et al. applied the direct torque control method to the control of AC induction motor based on the discrete space vector modulation technology, which reduced the torque ripple.

Vector control technology of permanent magnet synchronous motor

Vector control technology was born in the early 1970s. The transformation decomposes the collected three-phase stator current and flux linkage of the motor into two components according to the direction of the rotor flux linkage, which is the rotation vector. One is along the direction of the rotor flux linkage, which is called the direct-axis excitation current; the other is orthogonal In the direction of the rotor flux, it is called the quadrature torque current. Adjust the excitation current and torque current according to different control objectives, and then realize the precise control of speed and torque, so that the control system can obtain good steady-state and dynamic response characteristics.

According to different control objectives, the vector control algorithm of permanent magnet synchronous motor can be divided into the following types: id=0 control, maximum torque/current control, field weakening control Etc. These performance indicators can be achieved through independent control of the direct axis excitation current and the quadrature axis torque current.

Advantages

The permanent magnet synchronous motor can be integrally installed on the axle to form an integral direct drive system, that is, one axle is a drive unit, eliminating the need for a gear box. The advantages of permanent magnet synchronous motors are as follows:

Permanent magnet synchronous motors have high power efficiency and high power factor;

Permanent The magnetic synchronous motor generates little heat, so the motor cooling system has a simple structure, small size and low noise;

The system adopts a fully enclosed structure, no transmission gear wear, no transmission gear noise, and no transmission gear noise. Lubricating oil, maintenance-free;

The allowable overload current of the permanent magnet synchronous motor is large, and the reliability is significantly improved;

The whole The transmission system is light in weight, and the unsprung weight is lighter than that of the traditional axle transmission, and the power per unit weight is greater;

Because there is no gear box, the bogie system can be designed at will: Such as flexible bogies and single-axle bogies greatly improve the dynamic performance of trains.

Due to the use of permanent magnetic material poles, especially the use of rare earth metal permanent magnets (such as neodymium iron boron, etc.), its magnetic energy product is high and a higher air gap can be obtained Magnetic flux density, so when the capacity is the same, the motor is small in size and light in weight.

The rotor has no copper loss and iron loss, and there is no friction loss of the slip ring and brushes, and the operation efficiency is high.

The moment of inertia is small, the allowable pulse torque is large, the higher acceleration can be obtained, the dynamic performance is good, the structure is compact, and the operation is reliable.

Research hotspots

Motor torque characteristics

In order to improve the motor torque characteristics, many scholars and research institutions Bold attempts and innovations have been made in the structural design of the magnetic synchronous motor, and many new developments have been made. In order to solve the contradiction between the slot width and the tooth width, transverse flux machine technology was developed. The armature coil and the cogging structure are vertical in space, and the main magnetic flux circulates along the axial direction of the motor, which improves the motor's performance. Power density: The double-layer permanent magnet arrangement improves the quadrature-axis conductance of the motor, thereby increasing the output torque and maximum power of the motor; changing the stator tooth shape and magnetic pole shape to reduce the torque ripple of the motor, etc.

Field weakening expansion capability

After the use of field weakening control, the operating characteristics of permanent magnet synchronous motors are more suitable for the driving requirements of electric vehicles. In the case of the same power requirement, the inverter capacity is reduced and the efficiency of the drive system is improved. Therefore, permanent magnet synchronous motors for driving electric vehicles generally use field weakening for speed expansion. For this reason, domestic and foreign research institutions have proposed a variety of solutions, such as the use of a double stator structure and different windings at different speeds to maximize the use of the permanent magnet magnetic field; the use of a composite rotor structure where the rotor adds a magnetic resistance section to control The reactance parameters of the direct and quadrature shafts of the motor increase the speed expansion capability of the motor; the stator adopts deep grooves to increase the leakage reactance of the direct shaft to expand the speed range of the motor.

Motor control theory

Because of the characteristics of non-linear and multivariable permanent magnet synchronous motors, its control is difficult and the control algorithm is complex, and traditional vector control methods often cannot meet the requirements. For this reason, some advanced control methods have been applied in the permanent magnet synchronous motor speed control system, including adaptive observer, model reference adaptive, high-frequency signal injection method, fuzzy control, genetic algorithm and other intelligent control methods. These control methods do not depend on the mathematical model of the control object, and have good adaptability and robustness. They have unique advantages for systems with strong nonlinearities such as permanent magnet synchronous motors.