Introduction to thick film hybrid integrated circuit (HIC) technology

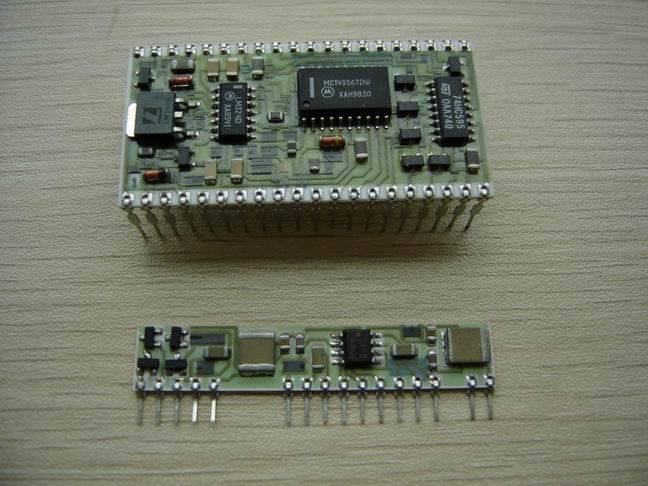

Introduce the concept of thick film hybrid integrated circuit (HIC) and the characteristics of the circuit, the production process and process, and the production process Various materials. At the same time, the application and development direction of thick film hybrid integrated circuits are introduced.

Overview

Integrated circuits are an aspect of microelectronics technology, and it is also a stage of its development. Microelectronics technology is mainly an electronic system composed of small electronic components. Integrated electronics is to complete the function of electronic circuits, forming a passive network on (or within) a separate substrate and interconnecting active devices with a specific process to form a miniature electronic circuit.

With semiconductor technology. With the advancement of small electronic components and printed circuit board assembly technology, electronic technology has achieved rapid development in recent years. However, too many connections. The solder joints and connectors severely hinder the further improvement of productivity and reliability. In addition, the improvement of working frequency and working speed further shortens the signal transmission delay time within the system. Therefore, these require fundamental reforms in the structure and assembly process of the electronic system.

Since the 1960s, thick-film hybrid integrated circuits have had a wide range of component parameters. High accuracy and stability. The circuit design is flexible. The development and production cycle is short. It is suitable for a variety of small batch production and other characteristics, and complements each other with semiconductor integrated circuits. Mutual penetration has become an important part of integrated circuits, widely used in electronic control equipment systems, and has played an important role in promoting the miniaturization of electronic equipment.

Although in terms of digital circuits, semiconductor integrated circuits have given full play to miniaturization. High reliability. It is suitable for high-volume and low-cost production. However, thick-film hybrid integrated circuits have maintained their position and characteristics superior to semiconductor integrated circuits in many aspects:

·Low-noise circuits

·High stability passive network

·High frequency linear circuit

·High precision linear circuit

·Microwave circuit

·High voltage Circuits

·High-power circuits

·Analog-to-digital circuit hybrid

As the scale of semiconductor integrated circuit chips continues to increase, it is a hybrid of large-scale and thick-film Integrated circuits provide high-density and multi-functional external components. Using thick-film multilayer wiring technology and advanced assembly technology for hybrid integration, the multi-functional large-scale hybrid integrated circuit made is the current and future development direction. A large-scale thick-film hybrid integrated circuit can be a subsystem or even a whole system.

Process

Thick film hybrid integrated circuits usually use printing technology to print patterns on ceramic substrates and sinter them at high temperatures to form passive networks. The manufacturing process includes:

·Planarization design of circuit graphics: logic design. Circuit conversion. Circuit division. Layout design. Plane component design. Discrete component selection. Consideration of parasitic effects at high frequencies. Consideration of thermal performance under high power. Consideration of noise under small signal.

·Production of printing screen: the graphic design of the plane is made on the stainless steel or nylon screen by developing method.

·Choice of circuit substrate and slurry: 96% alumina ceramic substrate is usually selected for the production of thick film hybrid integrated circuits (other substrates can be selected for special circuits), and the slurry is generally selected by DuPont of the United States . American Electronics Laboratory. The conduction belt of Nippon Tanaka Co., Ltd. Medium. Pastes such as resistors.

·Screen printing: Use a printing machine to print various pastes on the substrate through the screen printed with circuit patterns.

·High temperature sintering: The printed substrate is sintered in a high temperature sintering furnace to form a good fusion and network interconnection between the paste and the substrate, and to stabilize the resistance of the thick film resistor.

·Laser trimming: Use a thick film laser trimming machine to trim the resistance of the thick film resistor printed on the sintered circuit substrate to the specified requirements.

·Surface mount: use an automatic placement machine to assemble various external components and connectors on the circuit substrate, and complete the soldering through a reflow soldering furnace, including soldering lead wires.

·Circuit test: Test the various functions and performance parameters of the well-welded circuit on the test bench.

·Circuit packaging: properly encapsulate the tested circuit as required.

·Finished product test: retest the packaged circuit.

·Warehousing: Register the circuits that pass the retest into the warehouse.

Materials

In thick-film hybrid integrated circuits, the substrate serves to carry thick-film components. Interconnected. In high-power circuits, the substrate also functions as heat dissipation. The requirements of thick film circuits on the substrate include: flatness. High finish; good electrical performance; high thermal conductivity; thermal expansion coefficient matching with other materials; good mechanical properties; high stability; good processing performance; low price. Generally, 96% alumina ceramic substrates are selected for thick film circuits. If a substrate with better heat dissipation conditions is required, beryllium oxide substrates can be selected.

In the thick film hybrid integrated circuit, the passive network is mainly formed by printing various pastes on the substrate into a pattern and sintering at a high temperature. The materials used include: conductive paste. Dielectric paste and resistance paste, etc.

Thick film conductors are an important part of thick film hybrid integrated circuits, which act as interconnects for active devices in the circuit. Multi-layer wiring. Capacitor electrode. Lead bonding area of externally attached components. Resistor tip material. Low resistance resistors. Thick film microstrip and other functions. Among the conductive pastes, the usual thick film hybrid integrated circuits use palladium-silver materials, some military circuits and high-precision circuits use gold pastes, and some low-demand circuits use silver pastes.

Thick film resistor paste is also an important part of thick film hybrid integrated circuits. Thick film resistors made of thick film resistor paste are one of the most widely used and important components. Thick film resistor paste is composed of functional components. Bonding components. It is composed of organic carrier and modifier, generally the resistance paste of DuPont Company of the United States is selected.

The thick film dielectric paste is to realize the thick film of the thick film externally attached capacitor. The multi-layered conductors and the performance parameters of thick film resistors are not affected by the external environment. Including capacitor dielectric paste. Cross and multilayer dielectric slurries and encapsulation dielectric slurries.

Application

With the development of technology, the use of thick film hybrid integrated circuits is expanding day by day, mainly used in aerospace electronic equipment. Satellite communication equipment. Electronic computer. Communication system. The automotive industry. Audio equipment. Microwave equipment and household appliances, etc. It can be seen that thick film hybrid integrated circuits have penetrated into many industrial sectors. In Europe, the application of thick-film hybrid integrated circuits in computers dominates, followed by remote communication. Communication. Departments of military industry and aviation. In Japan, thick film hybrid integrated circuits are widely used in consumer electronics. The United States is mainly used for aerospace. Communications and computers, of which communications account for the highest proportion.

In the color TV industry, thick film circuits are generally used as power circuits and high-voltage circuits, including switching stabilized power supply circuits. Video amplifier circuit. Frame output circuit. Voltage setting circuit. High voltage limit circuit. Sound circuit and comb filter circuit, etc.

In the aviation and aerospace industries, thick film hybrid integrated circuits are due to the flexibility of their structure and design. Miniaturization. Lightweight. High reliability. Resistant to shock and vibration. Anti-radiation and other characteristics, in airborne communication. Radar. Fire control system. Missile guidance systems and communications between satellites and various space vehicles. TV. Radar. A large number of applications have been obtained in remote sensing and telemetry systems.

In the military industry, thick film circuits are generally used for high stability. High precision. Small size module power supply, sensor circuit, pre-amplification circuit, power amplifier circuit, etc.

In the automotive industry, thick film circuits are generally used as generator voltage regulators. Electronic igniter and fuel injection system.

In the computer industry, thick film circuits are generally used for integrated memory. Digital processing unit. Data converter. Power circuit. Thermal print heads in printing devices, etc.

In communication equipment, thick-film hybrid integrated voltage-controlled oscillators. Module power supply. Sophisticated network. Active filter. Attenuator. Line equalizer. Side tone suppressor. Voice amplifier. High frequency and intermediate frequency amplifiers. Interface impedance converter. User interface circuit. Relay interface circuit. Two/four wire converter. Automatic gain controller. Optical signal transceiver. Laser generator. Microwave amplifier. Microwave power divider. Microwave filter. Broadband microwave detectors, etc.

In the instrumentation and machine tool numerical control industries, thick film hybrid integrated circuits are generally used in various sensor interface circuits. Charge amplifier. Small signal amplifier. Signal generator. Signal converter. Filter. Power drivers such as IGBT. Power amplifier. Power converter, etc.

In other fields, thick film multilayer routing technology has been successfully used in the decoding of digital display tubes. Drive circuit, transparent thick film is also used for cold cathode discharge type. Electrodes of liquid crystal display tubes.

In addition, thick film technology also has the potential for sustainable development in many emerging edge disciplines that intersect with electronic technology. Related categories include magnetism and superconducting film devices. Surface acoustic wave device. Membrane sensitive devices (heat sensitive, photosensitive, pressure sensitive, gas sensitive, force sensitive). Membrane solar cells. Integrated optical path, etc.

Development

At present, thick film hybrid integrated circuits are also threatened by huge competition. The continuous improvement of printed circuit boards is chasing the development of thick film hybrid integrated circuits. In the context of rapid changes and fierce competition, it is necessary to further explore the problems of thick-film hybrid integrated circuits and the corresponding measures:

·Develop a variety of new substrate materials with low price and high quality. Paste and encapsulation materials, such as SIC substrates. Enamel substrate. G-10 epoxy resin board, etc., base metal paste. Resin paste, etc., packaging materials with good high-temperature stability and glass low-temperature encapsulation materials, etc.

·Using a variety of new chip components, such as micro-packaged devices (SOT), power micro-molded tubes, high-power transistors, various semiconductor integrated circuit chips, and various chip resistors. Capacitor. Inductors and various chip adjustable devices. R network. C network. RC network. Diode network. Triode network, etc.

·Develop and apply multilayer wiring. High-density assembly and three-dimensional circuits are developing towards large-scale thick-film hybrid integrated circuits with unit system functions.

·Give full play to the advantages of thick-film hybrid integrated circuits and continue to multi-function. The direction of high-power development, and continuous improvement of materials and processes, further improve product stability and reliability, reduce production costs, in order to enhance the vitality of thick film hybrid integrated circuits and competitiveness in the electronic product market.

·Based on the use of thick film integration technology, a comprehensive use of surface assembly technology. Thin film integration technology. Semiconductor microfabrication technology and various special processing technology, prepare many varieties. Multifunctional. High performance. Low-cost microcircuits, such as thick film microchip circuits. Thick film hybrid integrated circuits. Thick film sensors and various other new circuits, etc.

Promote the application of CAD.CAM and CAT technology in the design and manufacturing of thick-film hybrid integrated circuits, and the production process is gradually becoming mechanized. Semi-automated. Transition in the direction of full automation, continuously improving production efficiency. Reduce production costs and improve the reliability of thick film hybrid integrated circuits.